Whilst working at BMW I was lucky enough to do some work on one of my favorite cars, the BMW M4 Competition (F82) series. The BMW M4 is a high-performance version of the BMW 4 Series automobile developed by BMW's motor-sport division, BMW M GmbH. Part of the renumbering that splits the 3 Series coupé and convertible models from the 4 Series (to further differentiate it from the 3 Series), the M4 replaced the M3 coupé and convertible models.

3D Scanning & Modeling

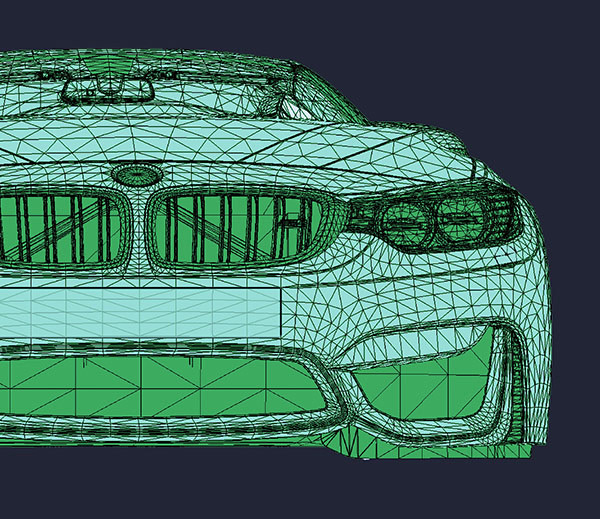

In order to create custom carbon fiber enhancements the current outer bodywork needs to be 3D scanned to form the basis of a realistic enough model from which to work. We used the Artec Eva, a portable 3D scanner ideal for making fast and accurate 3D models of medium sized objects, such as mid-sized automotive parts. It's used by many BMW sports divisions when creating performance racing vehicles.

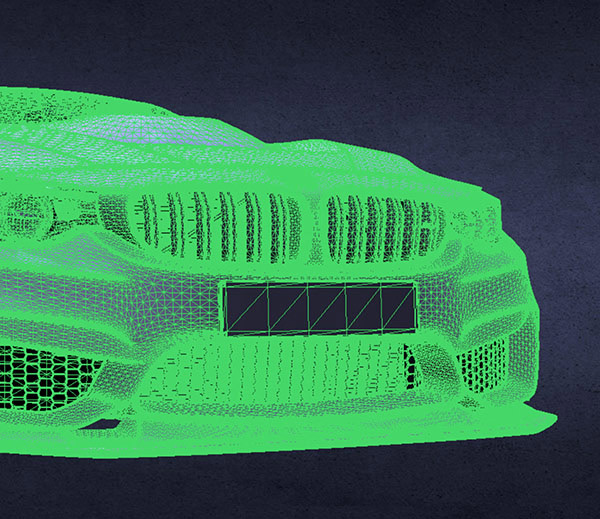

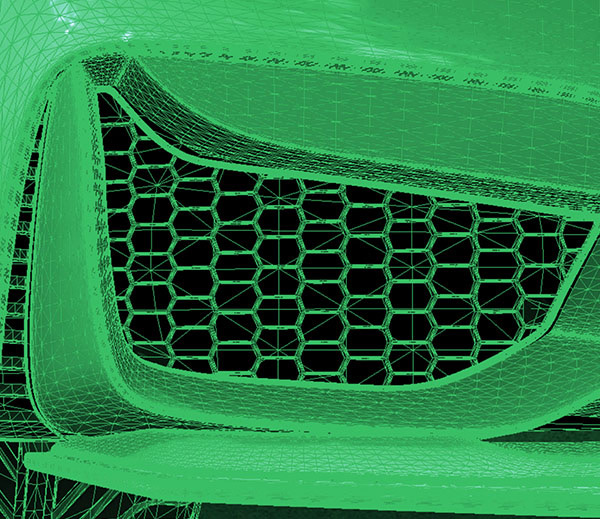

The Artec Eva creates a 3D render that was then loaded in to Blender (my choice). From here we were able to adapt missing elements from an existing 3D render to create a well rounded model with extremely accurate measurements. Final enhancements from further scans with details added helped create a more realistic virtual rendering. The front elements were then individually styled and applied to the model ready to be 3D printed for prototyping.

The final renders were mapped on to the vehicle to fine tune styling the various styling elements and get a good idea of the final product.

FRONT END STYLING

The 3D Blender model allowed me to test out results in a mid sized 3D printer to test the fitting against the existing chassis elements. Even using a larger than normal format 3D printer several sections were separately printed then glued together so see if they matched the existing front profile. Several prototypes were created before the final solution was decided upon.

Headlight eyelids trims with stereoscopic finish were re-shaped from existing BMW M3 parts and applied with 3M adhesive tape. This give the headlights a more aggressive profile without the weight changes that would come from restyling the bonnet lip. Similar trimming was applied to the upper and lower front splitters in order to compliment all the carbon styling integration.

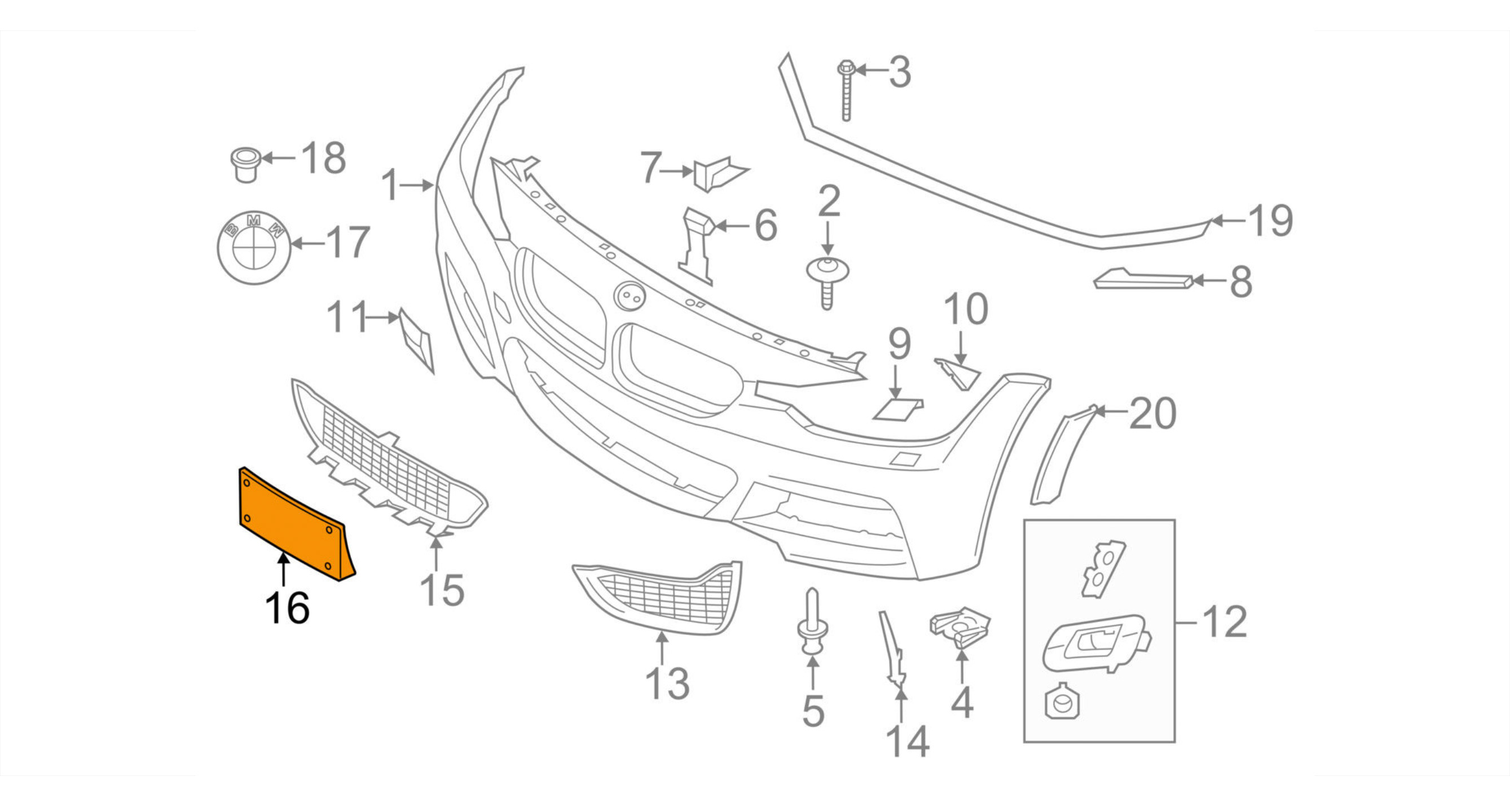

The front registration plate was removed along with the housing and plate bracket which exposed the drill holes and plate grooves. The grooves, markings left from the plate and drill holes were cosmetically repaired and the entire front section resprayed along with multiple housing elements and externally exposed internal elements.

The result of the front end styling was a more aggressive look and feel, larger ait intakes, a lower stance, increased down-forces and better airflow via the front lip in to the engine.

REAR END STYLING

The standard BMW M Performance rear diffuser exists in one part, but in order to create a more aggressive look and feel 2 extra side skirts were added to create a 3 part rear diffuser. A 3D printed prototype was created and temporarily bolted on to check the fitting. Unfortunately this fell off and the drill holes had to be resized multiple times before the final model was printed.

The final result was a more pronounced upward rear curve and aggressive styling. Minor aerodynamic improvements, albeit very slightly would aid to grip on the track.

FINAL TOUCHES

Paint Protection Film is a transparent, urethane material that can be applied to any exterior painted surface on vehicles. The film preserves the quality of the paint, creates a hydrophobic resistance to dirt and liquids and gives a longer lasting sheen and quality to the overall paint finish. Photographing the car created less marbling and the overall look appeared slicker, especially noticeable during sunrise and sunset times. Tyre graphics, deeper window tints, a STAGE ONE engine tune to take it up from 450bhp to 520bhp and a fuel efficiency increase of 18% added the final touches.